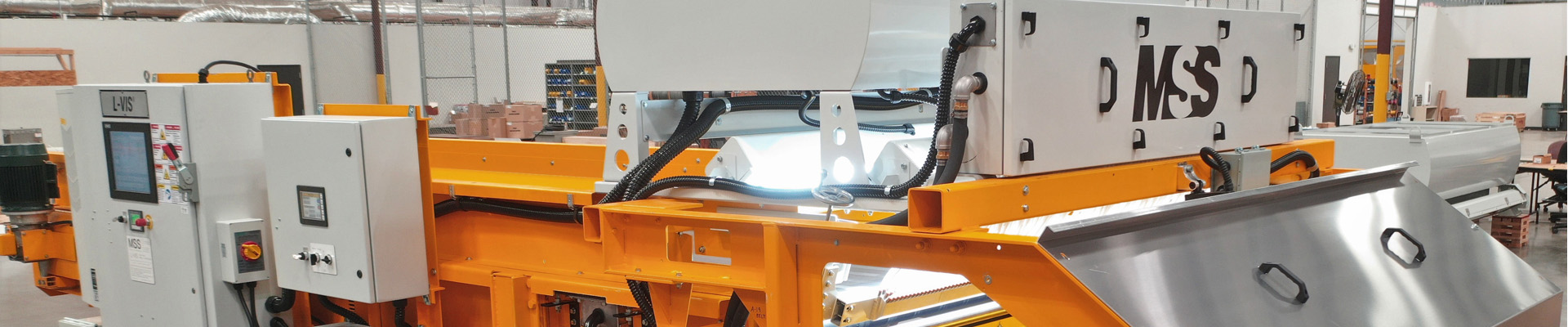

High-Resolution Color Sorting System for Small Particles

L-VIS™ uses high-resolution camera technology to provide accurate color and shape separation of small particles, capable of sorting even the smallest and thinnest particles, down to less than 1mm. The L-VIS® works great for color sorting applications such as Polyolefin (PE, PP) flakes and pellets as well as for PET flake. For electronic scrap applications, a proprietary algorithm is available for the detection of wires in electronic scrap.

Recent upgrades to both hardware and software of the L-VIS® high-resolution camera sorting system further improve the accuracy of color and shape separation of small particles. The most successful applications include extracting high-value commodities from electronic waste, such as circuit boards and copper wires, or sorting shredded or granulated plastics by color.

Our patented WireHawk™ algorithm extracts the smallest wires, and ColorMask™ illuminated reference technology allows the L-VIS™ to analyze and sort materials in flight, providing maximum flexibility.

WireHawk™

The patented WireHawk™ software algorithm is specifically designed for electronic and metal scrap applications.

WireHawk™ provides customers with increased recovery rates for even the thinnest wires, resulting in higher returns for high-value commodities. The combination of both WireHawk™ and ColorMask™ technologies opens the L-VIS® platform up to many other applications.

ColorMask™

ColorMask™ is MSS’s proprietary illuminated reference technology. The most recent design update features improved sorting accuracy for materials with difficult colors and weak contrast, such as dark green circuit boards and black insulated wires. The L-VIS® analyzes materials in flight over the ColorMask™ illuminated reference, which is adjustable in color and light intensity, for maximum contrast and accuracy.

Features

• In flight detection over ColorMask™ illuminated reference

• Increased recovery of electronic and metal scrap with WireHawk™

• Single-eject configuration

• Color touchscreen with remote Ethernet access

• Language selection

• Change recipes by the touch of a button

• Continuous automated internal calibration

• Software license never expires

• Statistics/QC reports

• All-metal detector upgrade available

• Split Configuration upgrade available

Specifications

• Machine width: 800–2000 mm (32–80 in)

• Efficiency*: Up to 98%

• Electricity: 5–8kW

• Compressed air: 100 psi / 7 bar

Capacities

• E-scrap*: 0.5–3.0 tons/hr

• Metal scrap*: 2.5–8.0 tons/hr

• Plastic flake*: 1.0–2.5 tons/hr

* Actual throughput and performance depends on a number of factors including, but not limited to, input material composition, particle size, bulk density and % of targeted materials.