Latest News

Keys to Building a Successful MRF: Before, During, After

When building a MRF, the goal is to end up with a facility that operates efficiently, requires minimal repairs and downtime, and flexibility to accommodate future equipment upgrades and modifications. Actively seeking out and incorporating practices from experts who focus on design, building, and managing MRFs will elevate the final product of your new, successful facility.

MSS Welcomes Patrick Nicol as Director of Technology, Ushering in New Era of AI Initiatives

MSS is thrilled to announce Patrick Nicol as Director of Technology, ushering in a new era of AI initiatives. With a passion for waste management and a background in engineering, Nicol aims to revolutionize recycling systems through automation and AI integration. His focus on system design improvement and the use of NIR optical sorters and AI vision systems will make recycling more efficient and intelligent. Nicol’s appointment reflects CP Group’s dedication to innovation and their commitment to meeting evolving client needs. Together, they are shaping the future of recycling technology.

Scipher Commissions Multi-Sensor Sorter for Difficult Plastic Stream

Scipher Technologies is tackling the challenge of separating and recovering fractions from hard plastics in e-waste. The company has commissioned a multi-sensor sorter, manufactured by MSS, which uses sensors and algorithms to scan and separate pre-processed fractions based on size, color, and metal content. This equipment produces a clean stream of recyclable single-polymer plastics, a significant achievement as bonded hard plastics are difficult to separate and recover. Scipher Technologies collaborates with local councils and B2B clients to source feedstock, and their export-quality plastic is sent to markets in Asia. The company is focused on developing solutions for e-waste plastics while supporting environmentally sound recycling practices. The MSS equipment provides excellent technical support, and Scipher Technologies aims to offer a complete solution for diverting waste from landfills and promoting a circular economy.

Sensor-Based Sorting Technologies for E-Waste Facilities

MSS MetalMiner induction sorter to extract residual metals from e-waste. Images courtesy of MSS.With the two main objectives being the recovery of as much value out of the mixed e-waste and the reduction in manual sorting stations, evolving technologies provide...

The Role of Mechanical Screening in the MRF of the Future

The recycling stream is changing and Material Recovery Facilities (MRFs) need to change along with it. As packaging changes and diversifies, the ability of traditional mechanical screens to produce finished end-products in a MRF is diminished, resulting in more...

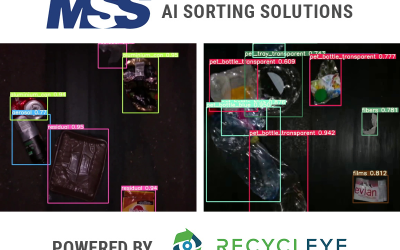

Recycleye and MSS announce ground-breaking partnership to revolutionize waste sorting

Leading US optical sorting equipment manufacturer MSS Inc. and ground-breaking British technology company Recycleye announce a strategic partnership in North America to combine their strengths and bring new technology to the waste sorting and recycling sectors....

Dynamic Pairings

Sorting success lies in pairing the right sensor technologies with the right method of extraction. At MSS Inc., we know the challenges presented by sorting recyclables at material recovery facilities (MRFs) can be approached in many ways. For 48 years, we have...

Optimizing Optical Sorters

Routine maintenance and periodic adjustments could help optimize optical sorters operating in material recovery facilities. With increasing age and hours of operation, the performance of optical sorters can start declining. General lack of cleaning and maintenance as...

MSS Receives Patent for PrecisionFlow™ Eject Hood Design

Patented hood for optical sorters works in combination with air-assist systems for precise material handling. MSS, Inc., the optical sorting division of CP Group, announced they received a patent for their PrecisionFlow™ eject hood for optical sorters. When processing...

Future-Proofing the MRF with FiberMax

MSS FiberMax™ optical sorter cuts costs while handling challenging materials and optimizing output quality (article published in Recycling Product News, April 2018) MSS, Inc., part of the CP Group and based in Nashville, Tennessee, is in the process of supplying a...